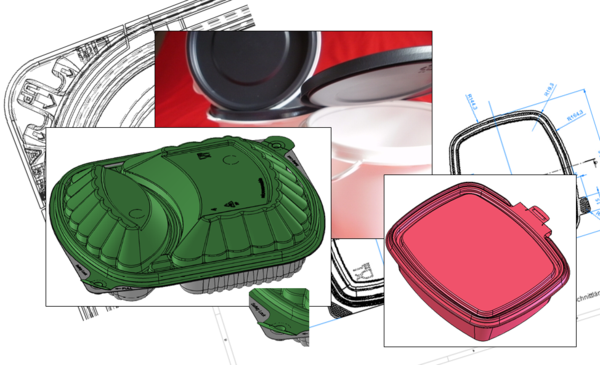

The NEW EFFICIENCY - new engineered Evolution Mold V4

Next level in Green Mold Technology for tilting and steel rule die molds.

Constantly high raw material prices and tough energy costs require new economical designs in the field of

thermoforming molds. This approach is also consistent with the desired smaller CO2 footprint in our society.

Through a combination of weight reduction and new tooling technology, new opportunities arise for significant savings potentials in the plastics processing industry.

10% less weight of the thermoforming mold = up to 15% less energy*

With optimized cooling and consistent lightweight of the tool. This results in a lower energy requirement for

cooling and machine power consumption.

Up to 10% less pressure air consumption*

Through optimal air inflow and reduced empty space in the compressed air sector.

Up to 15% less cutting-force*

With new cutting line geometries and new coating for the cutting parts, we can also extend the machine‘s

lifespan.

Up to 15% less film*

With a reduced distance between the bars and optimized transport capacity of the chain.

* According to normal standard mold technology and for most thermoforming products.

NEW TAMPER EVIDENT IDEAS

Tamper evident closure in thermoforming

- innnovative technology with servo motors

- optimization of the tool bottom portion control

- balance of unstable tool parameters (f.e. thickness and quality of the film)

- no interruption of the production process

- high reduction of the reject rate

- target-/actual values are recognized and differences will be compensated

immediately by the actuator - advantageous for the determined breaking point of the closure as well as

a seal edge design and many other functions

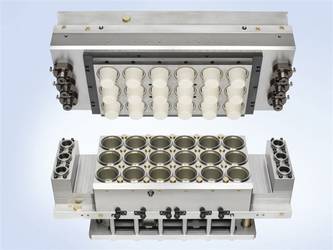

Thermoforming manufacturing program

As an independent mold manufacturer and competent partner to the packaging industry, we manufacture thermoforming tools as well as for special order-specific molds for the production of cups, bowls, lids and other forms of packaging, as well as prototypes, production tooling, tools for form-fill-seal lines, full size sets, strip cuts and stacking units for almost all common thermoforming machines.

KIEFER produces mold tools independently for the following manufacturers:

ILLIG: RV, RD, RDKP, RDK, RDM, HSA, UA, STAL, FS etc.

KIEFEL: KMD, KV, KTR, BSF, etc.

GABLER:D350, D450, F743, M90/91/92, Swing, Focus, Various etc.

WM: Flex, FC, FT, Intec etc.

BROWN: SR, T und R Serie

GEISS: twinsheet

GN: 2220C, 3021C, 1713C

IRWIN: model 28, model 44. NT, etc.